What SD-WAN Vendor Should UK Manufacturers Choose?

The manufacturing sector faces many networking challenges, including high reliability and uptime requirements, integrations with legacy systems, support for geographically dispersed locations and ensuring strict security is enforced.

As network downtime can lead to financial loss, halts in production and disruptions to supply chains, it is essential for manufacturers to find a network solution to prevent potential issues.

The best solution for this is Software-Defined Wide Area Network (SD-WAN), which not only addresses these challenges but also optimises network performance within your manufacturing environment.

Netify has compiled a list of the best SD-WAN vendors and managed service providers experienced in the manufacturing sector, including case studies, features and other data points specific to the industry.

SD-WAN Vendors for Manufacturers

| Vendor | About The Vendor | Why Their Solution Is Designed For Manufacturers | Case Studies | Key Offerings |

|---|---|---|---|---|

| Fortinet | The most security-focused vendor on the SD-WAN market, Fortinet has been recognised as a leader in the Gartner Magic Quadrant for its secure SD-WAN offering for the last five consecutive years. | Addresses manufacturing needs through: - Integrated security features to protect proprietary data and industrial systems - Self-healing network capabilities for continuous uptime |

An American manufacturer integrated Fortinet SD-WAN to achieve CMMC certification and retain defence contracts. | Application-Aware Routing, Unified SASE, Automation, App Path Insights, Identity-Based Firewall |

| Palo Alto Networks (Prisma) | Prisma SD-WAN offers AI integrations and detailed analytics to help manage networks, automating performance and resilience. | Provides advanced user experience monitoring, simplified operations, and native ZTNA 2.0 security integrations. | A global manufacturer protected critical plant operations with a Zero Trust approach, connecting manufacturing sites with hardware firewalls and SD-WAN devices. | Application-Aware Routing, Unified SASE, Strong Cloud Management |

| Barracuda | Strong integrations with Microsoft Azure, combining CloudGen Firewall and SD-WAN into a cloud-first single solution. | Ideal for manufacturers that utilise Azure services, with multi-cloud support and optimisations via Microsoft's Global Network. | Fibertex, a global textiles producer, implemented Barracuda SD-WAN to prevent costly downtime and improve analytics. | Azure Cloud-Native, Strong Cloud Management, App Path Insights |

| Versa Networks | Recognised for multi-tenancy support, ideal for service providers and enterprises managing many sites. | Supports complex, globally dispersed manufacturers via segmentation across data, control, and management planes. | Sprint (15,000+ employees across 50+ locations) implemented Versa SD-WAN with NGFW, UTM, and Bluetooth deployment. | Multicloud Support, ZTP, SASE Integration, App Path Insights |

| Cisco Catalyst | Enterprise-grade reliability and security, recognised as a leader in SD-WAN for large enterprises with thousands of sites. | Scalable for large, multi-site manufacturers; Cisco reports cost savings up to 39% and major WAN optimisations. | New Wave Group rapidly connected European sites while modernising cloud access. | Application-Aware Routing, Cloud OnRamp, WAN Optimisation, Identity-Based Firewall, Multiregion Fabric |

| Cisco Meraki | Easy-to-use SD-WAN platform with AutoVPN and centralised cloud management. | Ideal for manufacturers without dedicated IT teams, simplifies site connectivity and IoT integration. | A mid-size manufacturer reduced downtime by streamlining IoT and production line connectivity. | ZTP, CCTV Support, Sensor Integration, SASE Integration |

| HPE Aruba EdgeConnect | AI-powered optimisation for application performance, suited to mid-size businesses with limited internal expertise. | Supports SaaS optimisation, IoT, automation, and Industry 4.0 distributed platforms. | A global power solutions manufacturer deployed Aruba EdgeConnect across AWS, Azure, and Google Cloud. | Dynamic Path Selection, Unified SASE, WAN Optimisation, Cloud Vendor Integration, Enhanced Monitoring |

| VMware VeloCloud | Known for deployment flexibility across different clouds and high reliability. | Provides sub-second failover for highly precise production processes. | Redmond sea salt brand modernised infrastructure to run virtual desktops and voice apps simultaneously. | App Path Insights, Global PoP Network, Multicloud Support, Application Control |

| Aryaka | Known for global connectivity via 40+ PoPs and integrated SD-WAN + SASE as a managed service. | Strong for manufacturers in China and globally; multi-segment optimisation reduces latency. | Industrial manufacturer improved productivity and reduced TCO with Aryaka SD-WAN. | Unified SASE, WAN Edge Optimisation, Multicloud Support, Simple Management, Global PoP Network |

| Cato Networks | First SASE platform with global PoPs and all-in-one SD-WAN + SASE managed service. | Improves performance for manufacturers via global backbone and converged security/connectivity. | Alewijnse improved costs, complexity, and deployment times by migrating to SD-WAN. | Global PoP Network, Unified SASE, ZTP, Templated Configuration |

| Juniper Networks | AI-driven networking with automation and IoT integrations. | Marvis Virtual Network Assistant automates troubleshooting via NLP. | FloraCraft, a manufacturing leader, adopted Juniper wireless driven by Mist AI to improve operations and user experience. | WAN Edge Optimisation, Multicloud Support, Simple Management, AI |

| Citrix | Enterprise-grade SD-WAN supporting remote, branch, and edge use cases. | Ideal for edge computing in time-sensitive production processes. | Metrie reduced latency 57%, packet loss 93%, and jitter 21% across facilities with Citrix SD-WAN. | WAN Edge Optimisation, Multicloud Support, Simple Management, Edge Computing Support |

| Cradlepoint | Focused on 5G and LTE edge-to-cloud connectivity, ideal for mobile/remote manufacturing. | Supports multi-carrier cellular connectivity, crucial for remote sites. | Ericsson's USA 5G Smart Factory demonstrates private 5G-enabled smart manufacturing, boosting efficiency and productivity through automation. | 5G/LTE Connectivity, Wireless Edge, Cloud Management, Failover, IoT Integration |

| Peplink | Industrial-grade hardware for harsh environments with simplified deployment. | Reliability-focused SD-WAN for rugged industrial settings. | IoT manufacturer improved performance and uptime with Peplink's rugged solution. | WAN Edge Optimisation, Multicloud Support, Simple Management, IoT/Industry 4.0 Support |

| Forcepoint | Cybersecurity-driven SD-WAN with advanced data protection. | Ideal for manufacturers with strict IP and compliance requirements. | Italian appliance maker reduced MPLS costs via Forcepoint SD-WAN. | Integrated Cybersecurity, DLP, Cloud Security Gateway, Identity-Based Firewall, Threat Protection |

| Huawei | Global networking leader with industrial IoT support. | Supports distributed branches, IoT, and AI-driven traffic optimisation. | Sinopec Jiangsu deployed Huawei SD-WAN across 2,700+ sites, integrating 5G for smart gas stations. | IoT Integration, AI Automation, Edge Computing, Cloud Interconnectivity, High Availability |

| Nuage Networks | Nokia division focused on multi-cloud automation and SaaS optimisation. | Excels at flexible cloud onboarding for platforms like Office365 and Salesforce. | Ixom implemented Agile Connect (BT's Nuage-powered SD-WAN) for global visibility and security. | Multi-Cloud Automation, IoT Device Compatibility, ZTP, App-Aware Routing, Analytics |

Challenges That The Manufacturing Sector Faces

The manufacturing sector often faces many unique challenges and the impact of these challenges can be a strain on business activity.

Unique Networking Challenges in Manufacturing

Businesses within the manufacturing sector often require their network to meet many demands. These can include high reliability and uptime, integration with traditional networks, systems and equipment, support for diverse and geographically dispersed workforces, as well as integrating security solutions across the entire network to protect against threats from competitors and nation-state actors, aiming to access proprietary processes or trade secrets.

Impact of Downtime and Connectivity Issues

The impact of network downtime or connectivity issues can be severely damaging to manufacturing businesses. It is estimated that these issues can cause financial losses of up to $50,000 per minute due to production halts, supply chain disruptions and reduced operational efficiency. Interruptions to operations can also affect safety measures, which are required for manufacturers to maintain compliance with the Health and Safety at Work Act (HWSA), which mandates uninterrupted safety measures.

How SD-WAN Enhances Factory Automation

SD-WAN platforms offer a reliable, flexible and secure network infrastructure, which in turn provides many benefits over traditional WAN networks. By improving network reliability and performance, manufacturers can synchronise real-time systems to communicate data between sensors and machines. Through this real-time connection, manufacturers can create seamless automated operations, with systems that can rapidly respond to changes in environment.

We've covered more on how SD-WAN can be the solution for automating manufacturing processes here.

Through SD-WAN capabilities to support edge computing techniques, manufacturers can leverage localised processing of data, which reduces network traffic load and latency faced by critical traffic. This is important for businesses looking to utilise Internet of Things devices, such as for robotics or machine vision use cases, as these are heavily reliant on real-time connections and small delays can severely impact performance.

Whilst edge computing reduces the volume of traffic on the network, manufacturers may still be concerned about the communication traffic, which is critical to business operations, experiencing degradation. Dynamic and adaptive traffic management has become a necessity to avoid degradation and SD-WAN platforms assist with this through Quality of Service (QoS) policies, which enable prioritisation of automation data and communications between machines and control systems.

To improve automation efficiencies, manufacturers can utilise the monitoring functionality offered by SD-WAN. SD-WAN continues to monitor your network and control factory operations, even when your administrators can't, using real-time data visibility, telemetry and analysis of network performance. This enables manufacturers to be flexible, reconfiguring the network to support changes in demands, scale production lines and reach peak efficiency without having any major network overhauls.

What does SD-WAN do that improves operational efficiency?

For manufacturers concerned about the confidentiality and integrity of their production lines and intellectual property, SD-WAN also integrates vast security features and to reduce the complexity of setting up lots of security appliances, SD-WAN technology provides advanced security features that are pre-packaged. These can often include features such as Secure Web Gateway (SWG), Next-Generation Firewalls (NGFW) and Intrusion Prevention Systems (IPS). These security features are just some of many that ensure the protection of the network, ensuring that no breach of the system occurs. Other advanced security features include the use of Artificial Intelligence (AI) and Machine Learning (ML) for anomaly detection. These indicate potential threats to the network and, by allowing for proactive mitigation, SD-WAN enables administrators to rapidly respond to network threats.

Important Features To Consider For Manufacturing Networks

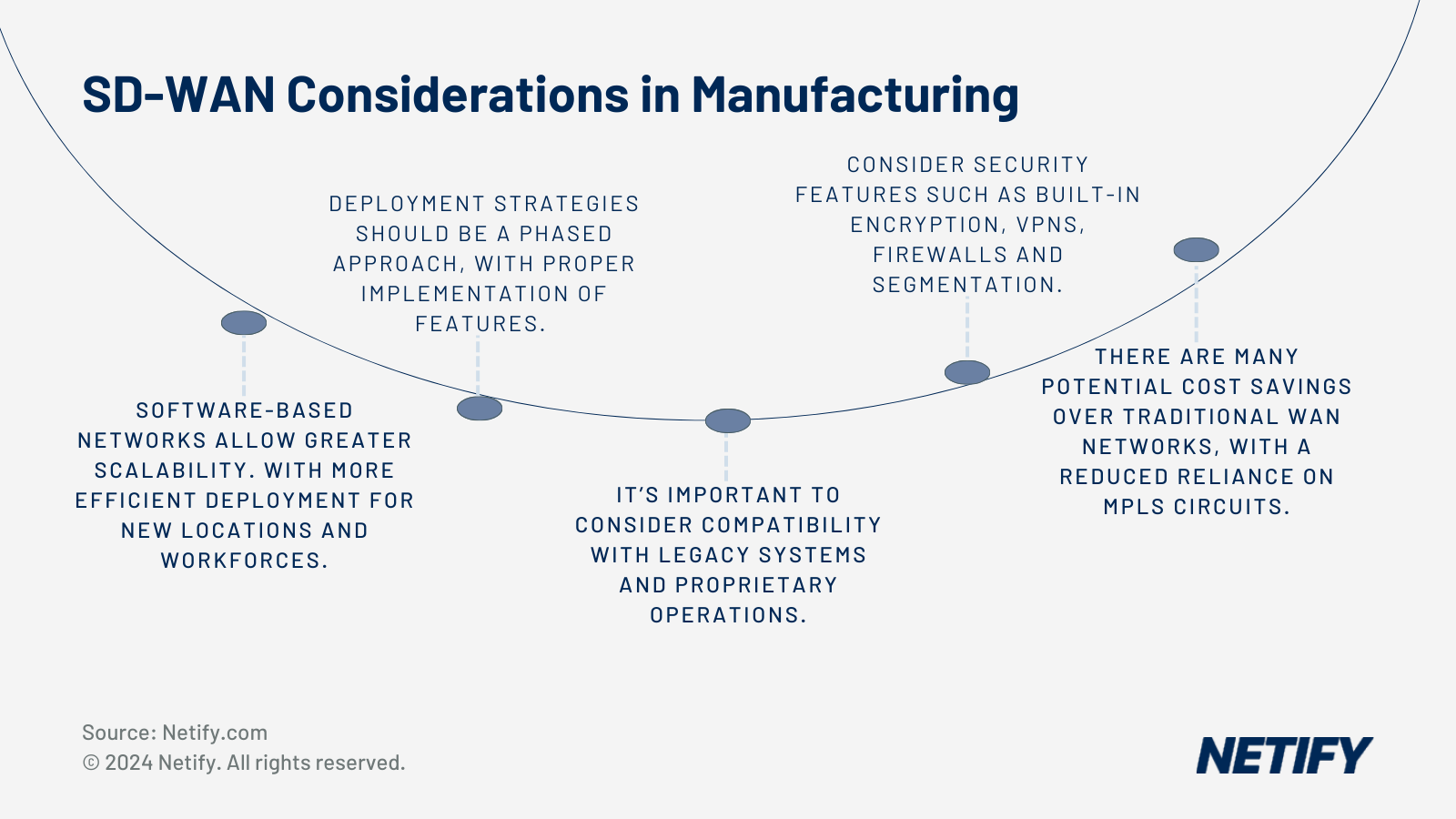

When choosing an SD-WAN solution for manufacturing, it's important to consider the most important facets of the network, such as requirements for uptime, security, connectivity between a range of locations or tech integrations in production lines.

Some of the more manufacturing-focused requirements include:

- Support for Industry 4.0, cloud and IoT integrations - Manufacturers are increasingly ditching their traditional systems for newer, more efficient processes. Industry 4.0 is the integration of digital technologies into manufacturing and industrial processes, such as IoT, AI, robotics and big data analytics. To support these technologies for manufacturers, a chosen SD-WAN solution must facilitate edge computing to process data closer to production sites, ensure compatibility with multi-cloud environments, enabling the integration of important cloud-based applications and platforms, as well as supporting low-latency IoT communications for real-time monitoring and control of manufacturing systems.

- Addressing challenges of legacy system compatibility - we're still seeing that many manufacturers are actually still heavily reliant on legacy equipment and systems that they've been using for long periods of time. These systems are vital to ongoing production and thus, taking them offline has been out of the question. Given this, for manufacturers that do utilise legacy systems, these systems may not easily integrate with some SD-WAN solutions and therefore manufacturers need to consider which solutions offer this capabilities. Compatibility can come in the form of Protocol support, which is essential for older systems to ensure easy integration without significant downtime.

- Security and data protection - Many manufacturers will be concerned about data security, with proprietary systems and intellectual properties on the network, it's essential that these are safeguarded from malicious activities by some form of security services. One way that SD-WAN handles this is through end-to-end encryption which protects sensitive production data, with granular access controls and segmentation backing this up to split up different parts of the network, preventing lateral movement between each section. Further to this, SD-WAN solutions often offer built-in security services, such as threat detection and response, to not only identify but also mitigate risks in real time, preventing data losses and assisting in recovery processes.

- Scalability and support for geographically dispersed operations - Manufacturing enterprises often span multiple locations, from factories to warehouses and distribution centres. To accommodate this distributed nature, SD-WAN solutions must provide secure remote working environment capabilities, as well as centralised management for operations across sites, with bandwidth optimisations that offer consistent performance across all facilities, regardless of geographic location.

SASE and SSE for Manufacturing

However, for manufacturers that require more in-depth security solutions, SD-WAN vendors may not offer the full solution - therefore businesses should look towards Secure Access Service Edge (SASE) and Secure Service Edge (SSE) solutions to improve the security services available across all fronts.

Not sure where to start? Check out our guide on choosing the best SASE vendors.

Manufacturers are increasingly using the cloud for its scalability, enabling Software-as-a-Service applications such as CAD to be cloud-delivered. Unfortunately, this alone is not truly scalable, as traditional WAN networks require additional security to be added to enable such activity. Security Service Edge, on the other hand, comprises of many security features that would enable manufacturers to utilise cloud applications. These features ensure the protection of the network through consistent policies across users and devices regardless of location. Features such as Secure Web Gateways (SWG), Cloud Access Security Broker (CASB), Zero-Trust Network Access (ZTNA) and Firewall-as-a-Service (FWaaS) enable Zero Trust policies to be implemented and reduce the need for additional security appliances to be integrated into the network, securing the manufacturer’s intellectual property from breaches.

SASE then integrates SSE as part of its solution with SD-WAN, providing users with a holistic network management tool, leveraging a combination of security and network performance benefits. This can be helpful for manufacturers looking to attain ISO/IEC 27001, as the ability to rapidly manage the entire network security demonstrates commitment to information security, a key aspect of the regulation.

Benefits of SASE/SSE for Manufacturing

For manufacturers, there is an increasing threat from competitors and nation-state actors attempting to gain access to proprietary manufacturing processes, designs and trade secrets. These actors often use espionage tactics to infiltrate networks in order to steal intellectual property and valuable manufacturing data.

Deep Dive: Some of the most common cybersecurity issues for Manufacturers.

Manufacturers therefore want to protect against cyber threats targeting their systems, such as industrial control systems (ICS). SD-WAN handles this through the enhanced security posture provided by the integration of ZTNA, SWG, CASB and FWaaS, which means that the network exposes less attack surface to potential threats.

Harry holds a BSc (Hons) in Computer Science from the University of East Anglia and serves as a Cybersecurity Writer here at Netify, where he specialises in enterprise networking technologies. With expertise in Software-Defined Wide Area Networks (SD-WAN) and Secure Access Service Edge (SASE) architectures, Harry provides in-depth analysis of leading vendors and network solutions.

Fact-checked by: Robert Sturt - Managing Director, Netify